Virtual Sensing for Predictive Maintenance using Machine Learning

Every year the US Army spends close to 60 percent of funds allocated for a given air platform on maintenance and sustainment. Helicopters like the HH-60 Pave Hawk and the UH-60 Black Hawk undergo maintenance every at pre-determined cycles and their mechanical and electrical components have a finite life expectancy. Accurate sensor data is critical to assessing current vehicle health and without that data, safety standards imply that one should assume “worst case” usage, which unnecessarily reduces life expectancy of components. For this reason, the Department of Defense (DoD) currently collects ample amounts of sensor data to monitor aircraft behavior and is in the process of shifting its operations from unscheduled & preventive maintenance framework (fix it when it breaks & fix it when it reaches a number of flight hours or cycles) to a “predictive framework”, where components are repaired or replaced only before they’re about to break.

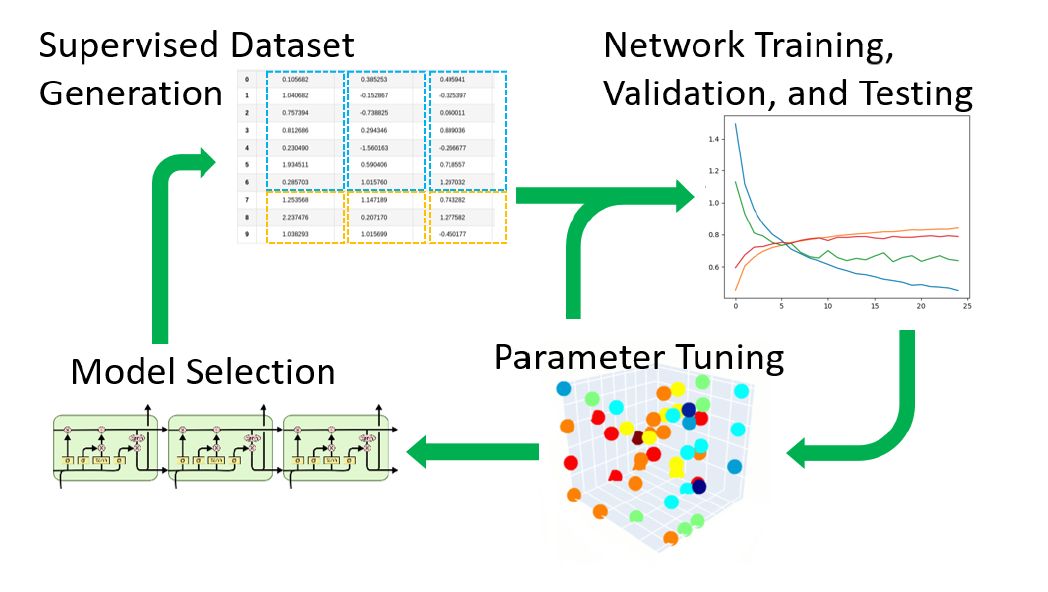

Because of the nature military aircrafts and their operation, it is common to have data gaps in the measurements and sensors failures. This is mainly due to the harsh environment where the sensors operate and the type of maneuvers the aircraft goes through in flight. To help mitigate this problem, the Joint Artificial Intelligence Center (JAIC) is sponsoring a project that leverages state-of-the-art machine learning (ML) and artificial intelligence (AI) for predictive maintenance. A team of researchers at the Georgia Tech Research Institute lead by Mr. David Alvord is developing virtual sensing techniques by combining AI, ML, and exploratory data analysis to develop a high fidelity predictive neural network model. The team’s primary objective is to create virtual sensor data for partial and full reconstruction of corrupted legacy data used for current condition based maintenance operating procedures. By leveraging the computational resources of the High Performance Computing Cluster of the US Army Engineer Research and Development Center, the team is using previously acquired flight sensor measurements to identify and characterize data dropouts, create a training set for supervised learning using Long Short-Term Memory models, and establishing the validation datasets for performance assessment. Results from this work are immediately applied to improve prediction of aircraft conditions and in the future may lead to improved vehicle flight time availability while decreasing required man-hour maintenance hours and overall cost.

The JAIC is the Department of Defense’s Artificial Intelligence Center of Excellence that provides a critical mass of expertise to help the DoD harness the game-changing power of AI. The mission of the JAIC is to transform the DoD by accelerating the adoption of ML and AI across he DoD and solve large and complex problems spanning multiple services.